Ing. Jiřina Princová

vedoucí odboru školství, mládeže, tělovýchovy a sportu

Kancelář 825

Zdá se, že používáte prohlížeč, který nepodporuje dnešní standard pro zobrazování obsahu na webu. To může způsobit, že některé části webu nemusí fungovat správně. Doporučujeme Vám prohlížeč aktualizovat nebo si stáhnout takový, který současné standardy splňuje.

V roce 2023 jsme usilovně pracovali na nové podobě a zpracování webového portálu pro náš kraj. Dovolte nám vám krátce představit, jaké důležité změny proběhly.

Celý portál dostal nový svěží design. Ten nyní více odpovídá naší vizuální identitě a současným trendům. Je přehlednější a umí se lépe přizpůsobit mobilním zařízením. V neposlední řadě je přístupnější lidem s různými postiženími.

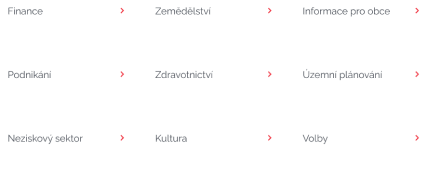

Připravili jsme pro vás novou sekci ‘Potřebuji zařídit’, kde naleznete všechna témata, která s námi nejčastěji řešíte. V každém tématu naleznete odpovídající informace, tipy, rady, dokumenty a kontakty.

V Libereckém kraji se toho hodně děje a my vás o tom rádi informujeme. Nově jsme naše aktuality rozdělili do tématických okruhů a vy tak budete moci snáz sledovat novinky v oblastech, které vás zajímají. Je to jednoduché. Vyberte si kategorii a čtěte.

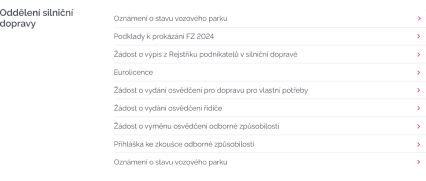

Hledali jste v minulosti pracně potřebné formuláře? Nyní už nemusíte. Odbory nově disponují sekcí sdružující veškeré možné formuláře na jedno místo. Formuláře jsou rozděleny dle oddělení, které je řeší.

Připravili jsme si pro vás specialitu v podobě přepínače barev. Kliknutím v pravém horním rohu menu si vyberte jednu ze dvou barevných variant.

Odbor se zaměřuje na vzdělávací a sportovní aktivity v regionu. Vykonává státní správu ve školství. Zajišťuje provoz škol a školských zařízení v Libereckém kraji, které zřizuje. Zároveň poskytuje metodickou pomoc také školám ostatních zřizovatelů v kraji i jejich zřizovatelům. Prostřednictvím dotací se podílí na financování sportovních i volnočasových aktivit mládeže, podporuje talentované děti, seniory i žáky se zvláštními vzdělávacími potřebami. Zajišťuje projekty ve vzdělávání.

vedoucí odboru školství, mládeže, tělovýchovy a sportu

Kancelář 825

sekretariát RNDr. Jiřího Čeřovského, náměstka hejtmana, resort školství, mládeže, tělovýchovy, sportu a zaměstnanosti

Kancelář 517

náměstek hejtmana, řízení resortu školství, mládeže, tělovýchovy, sportu a zaměstnanosti. Funkci vykonává od 1. 12. 2022.

Kancelář 518